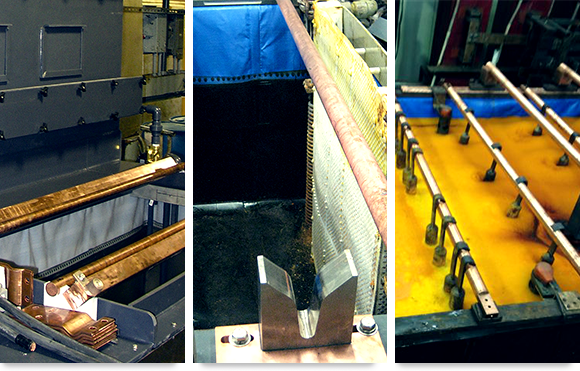

Primary Containment

Flexible tank liners from Witt Lining Systems offer a fast and long term solution for providing corrosion resistance to new tanks and extending the life of older, leaking tanks. Tank liners are custom fabricated for exact fit regardless of the size, shape or construction of your tank. A Witt tank liner isn’t bonded to the surface of the area, so little to no preparation is needed prior to installation. The substructure simply needs to be clean, dry, and free of any sharp impediments. In most cases the liner is fabricated in one complete piece allowing for easy installation.

Applications for Witt drop in liners include plating or metal finishing tanks, galvanizing tanks, anodizing tanks, chemical process tanks, and chemical storage tanks. Applications are also found in water treatment tanks/pits, cooling towers, and potable water tanks. Flexible liners are often the solution for tanks that aren’t well suited to a bonded liner or applied coating.